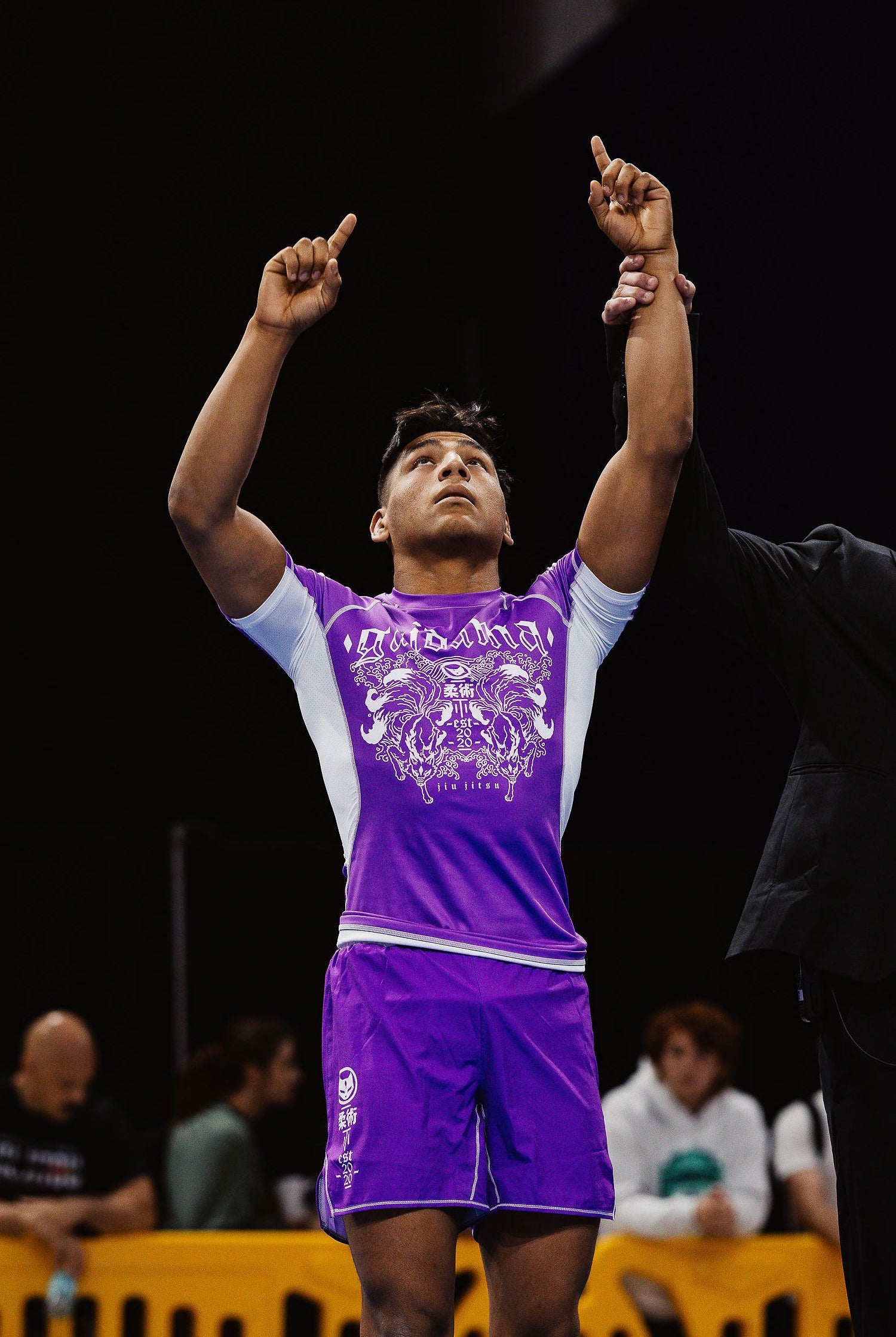

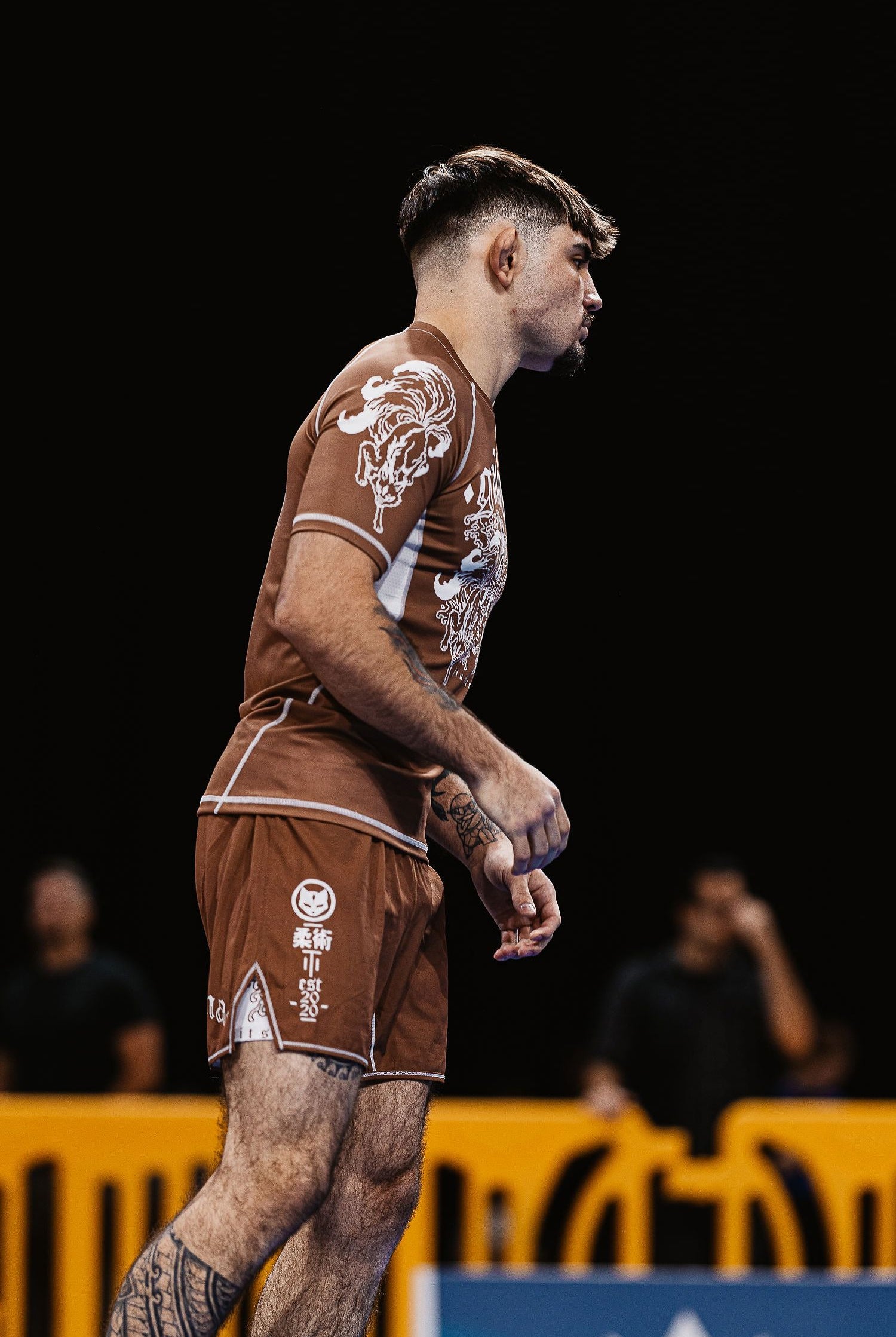

In the years since Gaidama founder Kendall Vernon established Brazilian jiu-jitsu’s now-beloved women’s gear brand, she’s had the pleasure of seeing her product cross international borders.

The global footprint of Gaidama’s impact is a reflection of the company’s values; indeed, athletes from all over the world can be spotted in competition on the international stage, proudly showing off their Gaidama gear. In fact, Gaidama’s first manufacturer was actually one that Vernon discovered overseas. Their relationship remains deeply special on both a personal and professional level to this day.

“Before I launched Gaidama, I scoured the globe for the right manufacturer. I prototyped with over 25 different companies before I found ‘the one’ – and I could not be happier with her,” shares Vernon. “Not only do I consider her a friend, her team’s craftsmanship is exceptional. I’ve actually had an established US-based textile operation – that specialized in athletic wear – tell me that even for twice the price, they could not guarantee the same level of quality as her.”

While she’s committed to her international manufacturing partners, Vernon also remains devoted to establishing and maintaining a strong “Made in the USA” line of Gaidama products. For Vernon, it’s as much about building a sense of community and shared history in her own backyard as anything else.

“Years ago, America used to be big into textile manufacturing,” explains the entrepreneur. “But we couldn’t compete with the prices of overseas manufacturing so the industry collapsed. In the last ten years or so, there has been an increased interest in American made soft goods, and thus a revival of textile based industrial towns across the US. Old mills are being brought back to life. Cut-and-sew operations are popping up in unexpected places. More and more American made products are making it to market. People see the Made in the USA label and feel a sense of unity and connection.”

That’s something that speaks to Vernon – and ultimately, to the vision she harbors for her company. “At Gaidama, we want to be a part of that energy,” she says. “It is an exciting industry to be revitalizing, even if you’re not a textile nerd like me. When we support American made soft goods, we are creating new jobs and resuscitating trade skills like sewing and pattern making.”

That said, the efforts – and long term investment – necessary for creating a sustainable Made in the USA label can be daunting. The price tag alone gives most small business owners pause.

“American labor is more expensive than it is overseas, and the majority of the price of sewn goods comes from labor costs,” Vernon explains. “And while we’re moving forward with the highest quality and lowest cost domestic cut and sew operation I’ve found so far, customers will still feel the burden of the U.S. cut and sewn price – even after trimmed profit margins on our end. It’s unavoidable.”

However, Vernon remains optimistic about the overarching direction of Made in America goods – and the willingness of a receptive customer demographic to pay a little extra to support business at home. “Gaidama’s Made in the US jiu-jitsu gear may not be for every budget,” she acknowledges. “But we’ll make it available in the way that we can for those who are in the market for it.”

In building Gaidama’s Made in America line, Vernon also makes a point of supporting her fellow small business owners. “One of the main differences between American textile manufacturing and overseas textile manufacturing is that the entire process from concept sketch to finished, packaged product is handled by a single, full-stack company overseas,” observes Vernon. “Not so in America. There are one or two big shops that do this kind of thing in LA, but I have avoided them for a couple reasons. Sure it would be more convenient – and so much faster! – to bring an American-made jiu-jitsu item to market – but at a cost.”

What kind of cost? Vernon is quick to elaborate: “These mega-companies charge a premium for the monopoly they have on convenient American made soft goods production – a premium that is inevitably passed on to the consumer. We’re trying to keep that out of the equation by taking the road less traveled: sourcing our own fabrics, creating digital patterns and tech packs here, prototyping there, comparing quotes and production capacities among specialty manufacturers, and so on.”

Working with a mega-corporation also simply fails to align with Gaidama’s ultimate mission and brand identity. “Working with smaller, specializing companies and building relationships with them along the way has been rewarding and meaningful,” says Vernon.

“There is a real sense of excitement and passion attached to every conversation we have with them because every party sees the partnership as an opportunity to propel our own grassroots mission forward and nourish the American textile industry from the roots,” she continues. “We’re growing together, synergistically, symbiotically.

“Together, we know that our project is directly creating jobs and feeding families. Yes, it is slower – sometimes frustratingly so – but it’s also famously rewarding. This approach also helps us keep the entire process leaner – which will ultimately offer our customers better prices.”

So, what’s on the immediate horizon for Gaidama’s Made in America line? The answer is a surefire crowd pleaser.

“Our first cut and sewn in the USA products will be women’s full-length grappling spats and short sleeve rashguards, two of our best-selling fits,” confirms Vernon. “Whether the first launch is in solids or prints has yet to be determined.

“We’re currently experimenting with sublimation dye printing on a handful of different fabrics to evaluate shrinkage, color richness, etcetera. In the meantime, we’re prototyping with a high-end fabric made from recycled plastic bottles. Whether the sub dye experiments finishes first or the recycled fabric prototyping finishes first will determine which direction we start in.”

That’s just the tip of the iceberg for Gaidama’s Made in the USA label. Vernon and her team are determined to use these products as a platform not only to support small local businesses and revitalize a lost sector of the American economy – but to diversify the affordably high-quality gear that her company is already so well-known for.

Now, that’s something every fox should be able to get on board with.